OPTICAL EMISSION SPECTROMETER

Home » X-RAY DIFFRACTOMETER SYSTEMS

RESIDUAL STRESS XRAY DIFFRACTOMETER

RESIDUAL STRESS XRAY DIFFRACTOMETER

* EN UNI 15305 and ASTM 915 compliant

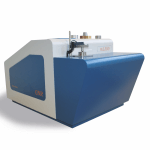

StressX is the Residual Stress Analysis instrument, providing a non-destructive test of the samples. Anthropomorphic 6 axis robot has been mounted to the head of the diffratometer that allows to analyze samples of any dimensions and shapes.

StressX can be design as in a closed cabin or on a four wheel trolley for onsite or laboratory analysis.

Residual Stress could be caused by machining, grinding, rolling, deep drawing, and welding, thermal hardening and shot peening. The device ensures that the user cans easily measures quantification to prevent fatigue damage and to control material's durability and safety.

StressX provides a flexible solution to residual stress determination on samples of any dimensions by the original synergy between compact X ray diffractometer and 6-axis robot.

6-axis robots ensures positioning accuracy and repeatability as low as 20 μm and positioning range as high as 895 mm radius from robot center.

Measuring target is defined by a combination of a Video camera for X-Y pointing and a laser for Z positioning.

Laser accuracy can be less than 10 μm and measuring range can be as high as 300 mm from the goniometer center.

Laser accuracy can be less than 10 μm and measuring range can be as high as 300 mm from the goniometer center.

The 6 degree provides a freedom the measuring positions and robot size may limit angular ranges.

Some specific applications of the Stress-X are listed below:

2161 Csomád, Verebeshegy utca 11, HUNGARY

info@unicore.hu

+36 20 364 9493

© Unicore.hu. All Rights Reserved. Designed by Bayraktar Tasarım